During the project term from 2018 to 2021, the market conditions, technologies and standards were analysed and experiences of the different disciplines exchanged in workshops. Based on these results, the consortium developed three Use Cases that address relevant issues and the interfaces between planning, production and building operation:

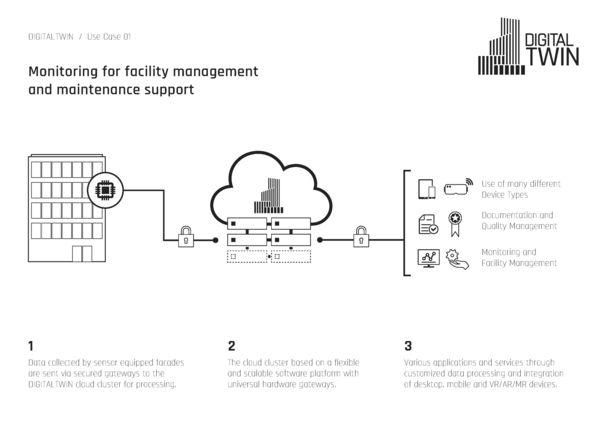

Use Case 1: Monitoring during building operation and maintenance support

Example of supervised façade

Use Case 1 addresses the easy availability and visualisation of live measured data at the building through the digital twin using edge cloud and cluster computing technologies.

read moreA multi-layered façade system ensures long-term, low-maintenance use. To offer the customer a maintenance service that is optimised and target-oriented, the conditions of the glass elements are continuously monitored. The acquisition of temperature, humidity and air pressure values also enables weather data to be recorded in detail for facility management. The shared use of measurement data by users, operators, product manufacturers and consultants is a typical use case for the development and management of a collaborative digital twin. This use case allows the development of the fundamental platform features (hardware connectivity, rights management, data safety and security), the integration of specific algorithmic analysis and the implementation of AR technologies (visualisation using a 3D model, remote access for maintenance support). The hardware infrastructure required will be implemented based on existing technologies.

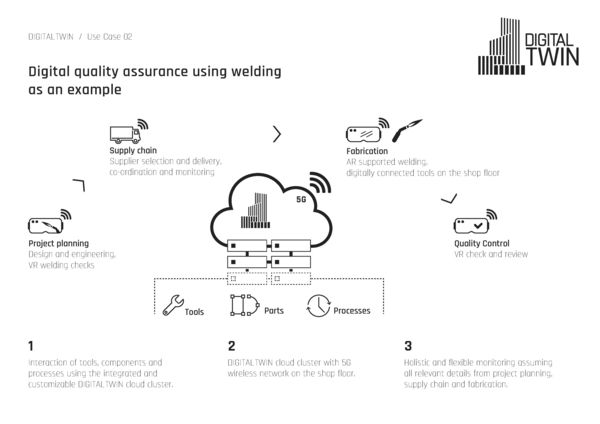

Use Case 2: Quality

Example of welding work and a virtual welding inspection on the shop floor

Use Case 2 includes a virtual welding inspection plus all documentation on the shop floor and the construction site in order to reduce the time during which inspectors must be present and achieve a continuous and effective workflow during the production and inspection of welded steel components.

read moreInspections will be in the form remote inspections of the welding seams using a precise digital twin. All information relating to planned and actual geometry, base material, tools and machines used, settings as well as measurement and scan data are provided for better inspection and complete documentation. This Use Case also investigates the capabilities of new computer vision technologies for applications under difficult operating conditions performing demanding quality assurance tasks.

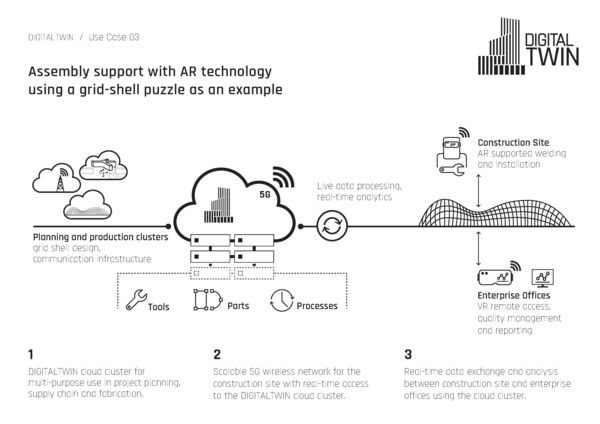

Use Case 3: Assembly support with AR technology at construction site

Example of a grid shell puzzle

Use Case 3 addresses the issue of more effective and efficient installation using the digital tools as well as flexible and safe use in harsh site environments.

read moreThe use of AR technology in safety goggles will enable users to find their way around the construction site. It will also provide additional information that is currently documented and communicated on drawings. A gridshell construction will be used to demonstrate a process chain from assembly planning and logistics to assembly support. Assembly personnel will be able to see installation sequences and identify and localise correct parts and tools. Furthermore, they can document various work steps, such as verifying the correct component position or correct tightening torques of bolts.

Demos

Demos have been developed for each use case as well as for the described task areas, which make relevant functions at critical interfaces comprehensible, integrate the systems in an application-oriented way and show the techniques and solutions in exemplary applications. This makes it possible to evaluate useful techniques, services and applications through the demos and at the demo building:

Use Case 1: Monitoring in building operation and maintenance support

- Demo: Façade monitoring with sensor networks and cloud cluster // Video clip

- Demo: Computing and bandwidth-intensive services in buildings with 5G radio technology and edge-cloud infrastructure // Video clip

- Demo: 5G-based localization using multi-antenna systems // Video-Clip

- Demo: Vernetzte Planung und Montage-Unterstützung bei Gitterschalen-Konstruktionen // Video-Clip

Use Case 2: Quality assurance in production

- Demo: Accessibility check for steel constructions and documentation // Video-Clip

Use Case 3: Assembly support with AR on the construction site

- Demo: Positioning and tolerance adjustment during the assembly of steel components // Video clip

- Demo: Information and communication technology on the construction site // Video clip

- Demo: Flexible 5G wireless access points on the construction site // Video clip